wankel compression test vs normal piston|first wankel engine : store If you know the design parameters for a Wankel, you can calculate the max theoretical geometric CR. I will agree with you that getting a theoretical geometric (Vmax:Vmin) CR above 12:1 is. Resultado da 2.1.5 Influence of an additional gate capacitor. The IGBT gate-emitter capacitor (CGE) and gate-collector capacitor (CGC) are optimized to let the IGBT7 have the full control of dv/dt, and to have an optimized switching waveform. Also the CGE is designed to be large enough to avoid parasitic .

{plog:ftitle_list}

NEROKO ESSA MUITO PERFEITINHA - LIVE COMPLETA NO PRIMEIRO COMENTARIO Locked post. New comments cannot be posted. Share Add a Comment. Be the first to .

Because there are no reciprocating parts — like pistons and connecting rods — the Wankel engine has little vibration. Accounting for the smaller size and lighter weight of a rotary engine, it.The compression ratio is the ratio between the cylinder volume with the piston in the bottom position, V bot (largest volume), and the top position, V top (smallest volume). The higher this .

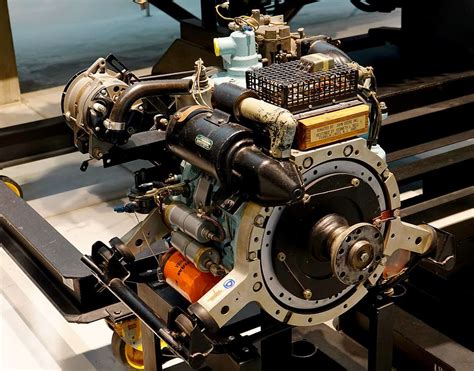

wankel engines

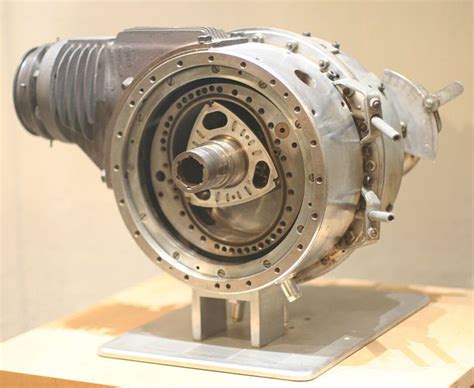

If you know the design parameters for a Wankel, you can calculate the max theoretical geometric CR. I will agree with you that getting a theoretical geometric (Vmax:Vmin) CR above 12:1 is.Advantages of Wankel Engine? The Wankel engine has a higher power-to-weight ratio. No reciprocating parts, resulting in less vibration and noise; More compact design than piston .Four processes of intake, compression, combustion and exhaust are executed successively in a different place of the trochoid housing. This is significantly different from the reciprocating .The Wankel engine (/ˈvaŋkəl̩/, VUN-kell) is a type of internal combustion engine using an eccentric rotary design to convert pressure into rotating motion. The concept was proven by German engineer Felix Wankel, followed by a .

The Wankel goes through the same four stages as a piston engine – intake, compression, combustion, and exhaust – using a bowed triangular rotor that moves around an oval housing (technically, an ‘epitrochoid’ shape, a word .

Wankel engine has a compression ratio from 9:1 to 11:1. Piston engine has a compression ratio from 8:1 to 12:1. They are capable of high RPMs and smoother power delivery. These have the ability to generate high torque at low .Geometric scheme of the best construction of Wankel combustion engines with rotary piston. Shape of surface of the cylinder is named as cyclic closed trochoids of first order constructed by two articulation elements. Shape of such surface out to have two lobs. A necessary condition for correct operation of the engines is theThe Wankel engine is a type of rotary piston engine and exists in two primary forms, the Drehkolbenmotor (DKM, "rotary piston engine"), designed by Felix Wankel (see Figure 2.) and the Kreiskolbenmotor (KKM, "circuitous piston engine"), designed by Hanns-Dieter Paschke [2] (see Figure 3.), of which only the latter has left the prototype stage. Thus, all production . A compression test is designed to reveal the condition of your engine’s valve-train and piston rings. Specifically, parts like intake and exhaust valves, valve seats, head gaskets, and the piston rings are common parts .

Normal. Compression builds up quickly and evenly, to the specified compression for each cylinder. Piston Rings Leaking. Compression is low, on the first stroke. Consequently, compression builds up with the following strokes, but does not reach normal. And, your compression improves considerably, when you add oil. Valves LeakingWankel engines burn oil by design, hence not only it had bad emissions, but also poor fuel economy. The RX-8 was specifically engineered to curb this, but even then it still had an obviously inflated value of 22 MPG (more like, half of that when driven how it should), when a typical 1.3L of a normal piston engine were more than 3x as efficient.

Porqué no evolucionó el desarrollo del motor rotativo Wankel y su comparación con el motor de pistones. #AUTOTECNICATV te lo explica claro y simple con el In. The rotary Wankel engine is an alternative of the reciprocating engine [].The Wankel engine can be used in conventional vehicle as well as in Hybrid Electric Vehicles (HEV) for range extended hybrid, designed for much lighter vehicles [].However, the uncommon geometry of the Wankel engine affects negatively the engine economy and the exhaust . 1. Introduction. The Wankel-type rotary engines are lightweight and have more compact designs, with fewer components, than conventional piston engines [1], [2].Since rotary motion can be obtained in Wankel Engines directly, there is no need to convert reciprocating motion into rotational motion as in reciprocating engines [3].Furthermore, Wankel engines can .

A compression test is simple to learn and only requires a few basic tools. From a mechanical perspective, you will need to know how to properly remove the spark plugs on the vehicle or equipment you are testing and properly disable the ignition system and fuel system, the latter if the vehicle is fuel injected. For carbureted engines, you can choose to disable the fuel supply .The design of the Wankel engine makes it far more powerful than a reciprocating engine of the same capacity. The NSU Wankel Spyder, with its 498cc engine giving a top speed of nearly 100mph, is one example. More recently, the Mazda RX-7 coupe has an engine capacity of only 1308cc (654cc per rotor), yet has similar performance capabilities to the Porsche 924S with a . Felix Wankel, a German engineer, came up with the Wankel engine in the 1950s.In a Wankel engine, fuel and air are compressed using a rotor that spins around a central driveshaft inside an oval .Wet Compression Test Diagnosis. The results of a compression test can be quite telling. The results shown below indicate the particular area that needs attention. Worn piston rings/cylinder walls: After running the first test, squirt a teaspoon of oil into the cylinder and rotate the crankshaft six turns. If the compression increases, the .

-These engines are not as effient as the Wankel engine in terms of the Otto Cycle. It takes to rotations of the crankshaft for the piston to have a power stroke in comparison to the Wankel engine having three power strokes per rotation Pros and Cons of the Wankel Rotory engine: Pros:-It has less parts and weighs less than the reciprocating engineGasoline octane requirements are higher than for piston engines, due to the high compression ratios required for rotary engines; Susceptible to “knocking” or “pinging” if not using premium gasoline. It has a lower fuel efficiency than a piston engine. It produces more emissions than a piston engine. It is less reliable than a piston engine. Wankel Engine Piston Engine; It has a rotary rotor which is used to convert the thermal energy into rotatory motion. . Wankel engine has a compression ratio from 9:1 to 11:1. Piston engine has a compression ratio from 8:1 to 12:1. They are capable of high RPMs and .Comparación de Eficiencia: Wankel vs Pistón. La comparación de eficiencia entre el motor Wankel y el motor de pistón es un tema de gran interés y ha sido ampliamente estudiado por investigadores e ingenieros por igual. Esta comparación involucra factores como el consumo de combustible y el impacto ambiental. Para comprender mejor estas .

To an unsuspecting driver, piston engines and rotary engines may look the same, but this isn't necessarily true. There are some key differences between them that you should know. What Is a Piston Engine? Also known .

D-B does not give a compression ratio for the Wankel, but if we were to assume about 10:1, the minimum volume between rotor and casing would be 60cc or 3.66 cubic inches. Familiarize Yourself with the Engine: Before starting the compression test, it is essential to have a good understanding of the engine’s layout and components.This knowledge will help you locate the necessary and access points for the test. Ensure Proper Ventilation: Compression testing involves running the engine, which produces exhaust gases.To prevent .

The intricacies of the defunct Wankel rotary engine . CarBuzz. Menu . A 1.3-liter traditional piston engine would struggle to deliver 100 hp, but a similarly-sized rotary engine packs a 232 hp .The Wankel engine is a type of rotary piston engine and exists in two basic forms, the Drehkolbenmotor (DKM, "rotary piston engine"), designed by Felix Wankel (see Figure 2.) and the Kreiskolbenmotor (KKM, "circuitous piston engine"), designed by Hanns-Dieter Paschke (see Figure 3.), of which only the latter has left the prototype stage. Thus, all production Wankel .

wankel engine design

This ensures that even a severely overheated Wankel engine cannot seize. 8. It has smaller frontal area than a piston engine of equivalent power. The simplicity of design and smaller size of the Wankel engine also allows for savings in construction costs, compared to piston engines of comparable power output. Disadvantages of Wankel Engine : The ORP engine also has a cylindrical combustion chamber, which resulted in increased brake thermal efficiency and decreased emissions compared to a Wankel rotary engine and traditional piston engines. In addition, this novel ORP engine achieved a higher power output per combustion cycle than Wankel rotary engines and conventional piston engines. A compression test reveals the condition of your engine's valves, its valve seats, and piston rings and whether these parts are wearing evenly. Healthy engines should have compression over 100 psi .

Motores de pistones vs. motores rotativos: Diferencias, ventajas e inconvenientes Álvaro Prieto Amaya Graduado en Administración y Dirección de Empresas y Derecho, se define como un apasionado de los vehículos desde su infancia, cuando recibió su primer coche como regalo. Con más de 8 años de experiencia escribiendo para Autonoción, Álvaro se ha convertido en un .Rotary vs Piston. PROS • The nature of the engine means that a much smaller displacement can produce considerably more power than a comparably sized piston engine - a Mazda RX-8 is technically a 1.3litre, yet produces around 230bhp. • The engines are much smaller, lighter, and (in theory!) have many less moving parts to go wrong.

Of course, it did take some effort from Dr Wankel to make it more practical. By 1967, the rotary engines were a commercial success due to Mazda. . Rotary Engine vs Piston Engine. . In fact, the upcoming engine is in line to be used as a prototype to test and extend the range of Mazda’s electric car, MX-30.

compression test snow

first wankel engine

WEB1,404 baby paloma pelada FREE videos found on XVIDEOS for this search.

wankel compression test vs normal piston|first wankel engine